Compaction, granulation, crushing and filling

System partner for compaction and granulation machines

Alexanderwerk's core area of expertise is related to mechanical processing of raw materials. This involves machines for particle size enlargement (e.g. roller compactors, moist granulation machines) or for particle crushing (e.g. rotor fine granulators, grater/shredders, toothed disc crushers).

Compaction in the pharmaceutical sector

The cantilevered rollers allow easy cleaning when changing products. Careful selection of the best materials ensures high acceptance of the systems in the GMP sector. In combination with the latest technology, these ingenious and proven systems ensure outstanding ease of use.

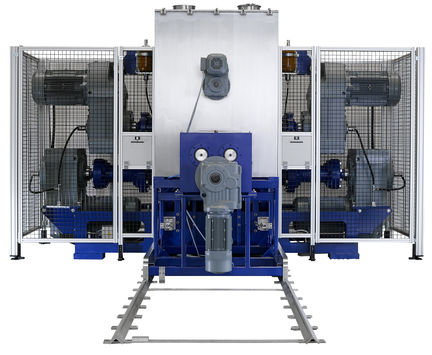

Compaction in the fields of chemicals and fine chemicals

The fully supported rollers allow high product throughput capacities. This is especially applicable for mono products in the fields of chemicals and fine chemicals. The newly designed machine provides a high level of functionality combined with extremely short manipulation times.

Grater/shredders

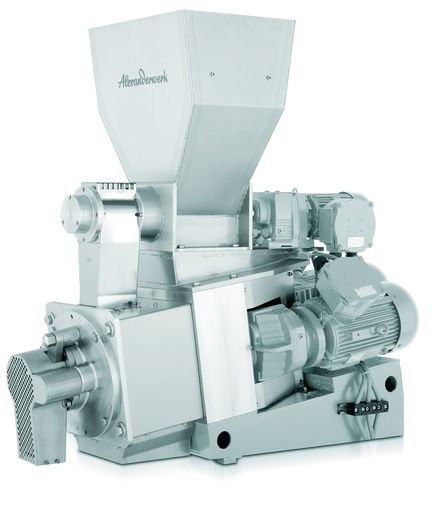

Rotor fine granulation in Diagonal-Design®

An important element of machines from Alexanderwerk is their crushing technology involving granulation, grating, shredding and cutting.

Unlike conventional designs in which at least 50% of the crushing process takes place only within the working surface in the third quadrant, the effective working surface is significantly increased during granulation based on Diagonal-Design®. The rotor fine granulator increases the performance by up to 100%, and also produces more gentle crushing with less fine particles. This helps to minimise the investment costs and boost the quality of the finished product. Furthermore, the modular design allows fast changing and cleaning of all working tools and thus meets the prerequisites for flexible work.

Alexanderwerk's patented Diagonal-Design® delivers up to 100% higher throughput capacities compared to the conventional design.

Moist granulation machines

Alexanderwerk AG

Roller compactors, rotor fine granulators, moist granulation machines, grater / shredders